A solid-state laser known as a ruby laser uses a man-made ruby crystal as its gain medium. Theodore H. “Ted” Maiman developed the first operational laser at Hughes Research Laboratories on May 16, 1960. It was a ruby laser.[1][2]Ruby lasers emit pulses of intensely red coherent visible light with a wavelength of 694.3 nm. The average ruby laser pulse lasts for about one millisecond.

Advertising

Advertising

Introduction

In order to generate a population inversion, a ruby laser typically consists of a ruby rod that must be blasted with extremely high energy, typically from a flashtube. The rod is frequently sandwiched between two mirrors to create an optical cavity that oscillates the fluorescence light from the ruby, stimulating emission. Ruby is one of the few solid state lasers that emits light in the visible region of the spectrum at a wavelength of 694.3 nanometers, with an extremely small linewidth of 0.53 nm and a rich red colour.The ruby laser is a solid state laser with three levels. A synthetic ruby rod is used as the active laser medium (also known as the laser gain/amplification medium) and is energised through optical pumping, often by a xenon flashtube. At 400 and 550 nm in the optical spectrum, Ruby possesses extremely strong and broad absorption bands and a very long fluorescence lifetime of 3 milliseconds. Since the pulse duration can be significantly longer than with other materials, this enables very high energy pumping. Despite having a very broad absorption spectrum, ruby has a substantially poorer conversion efficiency than other media.

Ruby Laser – Definition, Construction and Working

Ruby laser definition:-

A ruby laser is a solid-state laser that uses the synthetic ruby crystal as its laser medium. Ruby laser is the first successful laser developed by Maiman in 1960.

Ruby laser is one of the few solid-state lasers that produce visible light. It emits deep red light of wavelength 694.3 nm.

Construction of ruby laser :-

The laser medium, the pump source, and the optical resonator are the three key components of a ruby laser.

Laser medium or gain medium in ruby laser:-

A single cylinder-shaped crystal of ruby (Al2O3: Cr3+) serves as the laser medium or active medium in a ruby laser. The host sapphire (Al2O3) that makes up the laser medium (ruby) in the ruby laser is doped with trace amounts of chromium ions (Cr3+). The ruby is thermally efficient.

Ruby laser treatment:-

When used to treat a variety of dermatological problems, LASERs (light amplification by stimulated emission of radiation) are sources of intense monochromatic (single wave length) coherent light. Their application is based on the laser’s wavelength, pulse parameters, fluence (energy output), and the type of the condition being treated.

There are many distinct types of lasers; they are distinguished by the medium in which the laser beam is produced. Depending on their wavelength and penetration, each type of laser has a distinct variety of applications.

How does the ruby laser work?

- Selected thermolysis is the basis of the Q-switched ruby laser’s (QSRL) dermatological uses. The process of creating powerful laser beams in incredibly brief pulses is known as Q-switching.

- High output energy (100–200 MW) is possible at very brief pulse periods (20–80 nanoseconds) at a wavelength of 694 nm thanks to the active medium (a ruby crystal).

- When compared to surrounding tissue, the target structure (also known as a chromophore) absorbs a significant amount of the laser light at the chosen wavelength.

- The thermal relaxation time of the target structure, which is the time it takes for the target to cool by 50% of its peak temperature after irradiation, is less than the laser energy pulse duration.

- Due to the shorter pulse duration, it is guaranteed that only the target structure will be affected by the heat energy and not the tissue around it.

- Ruby laser light may be reflected, transmitted, or absorbed when it comes into contact with skin. The therapeutic effect is mostly attributable to absorbed energy since it is transformed by the desired targets (chromophores) into thermal energy (heat), which kills the sick cells.

- Haemoglobin, melanin, and tattoo ink are the three skin chromophores that the ruby laser most frequently targets. Each of these substances has a distinct laser light absorption spectrum.

- When energy meant for the target chromophore is nonselectively diffused and absorbed by nearby tissues and structures, complications occur.

The First Ruby Laser

The first laser in history—also referred to as the “ruby laser”—was created by Theodore Maiman in 1960. Aluminium oxide, in which part of the aluminium atoms have been swapped out for chromium atoms, makes up ruby crystal. The ruby’s vivid red hue is derived from chromium. A cylinder-shaped ruby crystal is created in a ruby laser. On one end, a mirror that entirely reflects light is set up, and on the other, a mirror that partially reflects light. A white light flash that starts the laser action is produced by a high-intensity bulb spiralled around the ruby cylinder.

The green and blue wavelengths in the flash raise the energy level of the electrons in the chromium atoms. The electrons release their distinctive ruby-red glow as they return to their regular form.

Ruby Laser Brown Spot Treatment New York, NY

WHAT IS TREATED BY THE RUBY LASER?

- While the Q-switched Ruby laser is quite effective at erasing tattoos, this is not its sole advantage. Additionally, the Ruby laser can handle

- coloured lesions

- Birthmarks

- Moles

- Macules of Ota’s coffee nevus

- Discolorations on the tongue

PUBLICATIONS

Journal Articles “Successful Treatment of Cosmetic Oral Mucosal Tattoos Using QS 694-nm Ruby Laser and 755-nm Alexandrite Picosecond Laser.” 30 December 2019: Lasers in Surgery and Medicine.

“Tattoo formation from synthetic suture and successful removal with Q-switched ruby laser.” Dermatologic Surgery, December 1996.

“Q-switched ruby laser treatment of small and medium-sized congenital nevi.” 1996. Arch Dermatol.

“Q-switched ruby vs. Q-switched Nd:YAG laser in the treatment of tattoos.” Cutis. 1995.

“The traumatic tattoos treated with the Q-switched ruby laser.” 1993. Plast Reconst Surg.

“Q-switched ruby laser therapy for nevus of Ota.” 1992’s Arch Dermatol.

“The use of a Q-switched ruby laser in the treatment of pigmented lesions of the mucous membranes.” 1992. J Am Acad Dermatol.

A Brief History Of The Ruby Laser

Ruby lasers were the first lasers ever created (after the maser). The substance in the laser that is activated and used to make the laser light, in other words, is what this signifies. Aluminium oxide, the material that makes up ruby rods, contains chromium in place of the aluminium atoms that give aluminium its distinctive red colour. The laser cavity has a ruby rod sandwiched between two mirrors that are both totally and partially reflective. Light is flashed around the ruby rod using a flash lamp, causing the electrons in the chromium atoms to become more energetic. They emit light as their energy levels decrease. Through the use of mirrors, this light is reflected back and forth inside the laser chamber. Light is let through the somewhat reflective surface.Theodore Maiman, who created the ‘ruby laser’ mentioned above, created the first laser in 1960. Physical Review Letters rejected his brief study on the laser at the time that he was working at the Hughes Research Laboratory in California. This is believed to be the case since there was a cut-off placed on the number of papers they could get because they were receiving a large number of papers on the maser, or “microwave wavelength laser,” at the time.Funny enough, the Hughes Research Laboratory formally unveiled the ruby laser to the press media during the summer of 1960, sparking a flurry of conversations about death rays. The ruby laser produced laser pulses of the order of a few milliseconds since it made use of flash lamps. Since then, lasers have employed a variety of techniques to cut the pulse length to attoseconds. In other words, one second divided by one, then 18 zeros.

Giant 13kJ RUBY LASER CANNON! Test Shots and Overview!!

It Happened Here: The Ruby Laser

A retinal tumour was removed with a medical laser for the first time.

Lasers are widely used today. In addition to the medical industry, where they are frequently used, you can also find them in scanners, DVD players, and even presentation points. However, they weren’t always so common. The world’s first functional laser was built in 1960 by Theodore Maiman, a worker at the Hughes Research Lab in California, using synthetic ruby as the lasing medium. Then, everything was different. Following Maiman’s discovery, researchers raced to develop applications for the laser, particularly in medicine.

Dr. Charles J. Campbell of the Edward S. Harkness Eye Institute used the powerful beam of light for the first time in medicine the following year at what was then known as Columbia-Presbyterian Medical Centre (now NewYork-Presbyterian/Columbia University Medical Centre). On November 22, 1961, Campbell used the laser to treat a patient’s retinal tumour while collaborating with Dr. Charles Koester, a representative of the company that had provided the laser. With a single pulse that lasted around one thousandth of a second, the tumor—an angioma—was eliminated. The 1,000-watt xenon arc lamps that were being used in comparable operations were much less comfortable for the patient than the laser, which was also extraordinarily quick. The ruby laser was applied in numerous medical procedures throughout the ensuing years. Along with its ongoing use in ophthalmology, including LASIK, it is frequently used to treat cancer and perform procedures in the specialties of gynaecology, dermatology, and gastroenterology.

As a graphic design software for the laser machine, Ruby® guarantees a seamless workflow.

As a graphic design software for the laser machine, Ruby® guarantees a seamless workflow.

Create graphics, text, and design components. With the integrated workflow, modifications may be made rapidly. The Ruby® software, a graphics and laser programme, allows you to alternate between the “design” and “prepare” processes at any moment. Has all the graphics equipment required for laser users. The time it takes to go from having a concept to having a final product is halved by these features.

Work independently. Multiple users on multiple machines.

Ruby® creates a network that connects all of your laser equipment. From a PC or Mac, you can divide jobs among other devices. Without a separate PC, jobs are processed on the integrated memory of the Trotec Run on Ruby® laser equipment. Jobs can now be planned by one user and generated by another anywhere and at any time within the same network thanks to the new workflow.

The user interface will delight you :

From conception to completion, the user is assisted by the Ruby® laser software. The design process is the beginning of the smooth workflow, which continues through preparation and production. Self-explanatory. There is not much training needed. Right instantly, the best laser results are guaranteed by the cloud-based material database. The material and material effect, such as deep engraving, dark engraving, or kiss cut, are chosen by the user .

Creating graphic and text elements :

Ruby® is a cutting-edge laser workflow programme that frequently offers all the graphics tools required to create designs, graphics, photos, and text elements, eliminating the need for time-consuming switching between laser and design programmes, especially when making changes to designs or laser jobs. Popular design programmes like CorelDraw, Adobe Illustrator, and AutoCAD, as well as vector file types like SVG and PDF and non-vector file types like JPG, PNG, and BMP, are all easily compatible with Ruby software. Errors are automatically detected and repaired when files are put into Ruby software, optimising them for the laser machine, including line thickness and colours.Ruby® software allows users to quickly alter imported designs when necessary, negating the need to switch between various software programmes in order to perform numerous file alterations, even while it does not replace advanced graphic software packages. The design process is greatly streamlined as a result, saving time and effort.

No hairlines, no RGB color code, no more configuring the sheet size.

Without a printer driver, you can import files like pdf, svg, png, jpg, cdr, or ai directly into Ruby®. It is skipped over the laborious process of printing laser jobs from the graphics programme. Errors are automatically optimised for the laser machine when files are loaded.

Import formats printer driver >10 0

Mac, Tablet, PC

Create your laser jobs on a Mac, process them on a PC in your production department, and monitor the status of your laser on the move with a tablet. Ruby® can run on Windows, Linux, or Mac without regard to the client or platform. all computer operating systems.

1 operating systems and platform clients

Access anytime and anywhere

Within the same network, prepare your laser jobs from any location. With Ruby®, you don’t have to be standing next to the laser machine to create architectural model drawings remotely, trim tasks in the graphic prepress office, or accommodate last-minute customer modifications before production. Anywhere on the same network can utilise Ruby®.

1 locations to prepare the network

Multiple users

With various roles and permissions, you may collaborate as a team. For instance, operators can only change the laser job settings; they cannot change the saved material database. Production using lasers and graphic prepress go hand in hand. One laser machine, many users.

1 0 laser barriers

What is the Sinon Ruby laser?

The ruby laser, as its name suggests, generates light with a wavelength that resembles rubies (694 nanometers).

There are numerous medical lasers available, each of which is intended to treat a unique issue. The Sinon Ruby laser will be covered on this page.

Tattoo and skin pigmentation removal are the two principal applications for the ruby laser.

The capability of having; is one of the features of this laser.

- High power, extremely brief pulses that can last under 20 nanoseconds (one nanosecond is one billionth of a second). This enables the laser to literally break the pigments or inks used in tattoos and skin pigmentation through a photo-mechanical effect. The immune system of the body then eliminates the leftovers.

The overall operation of the laser light is based on the idea of selective photothermolysis, which is the attraction of specific laser wavelengths to specific colours, enabling the targeted heating of coloured objects.

The laser’s depth of penetration is also crucial. The penetration increases with wavelength length. Therefore, compared to the 532nm wavelength, the 694nm wavelength penetrates far deeper. This is crucial for deeper pigmentation issues such birthmarks, Naevus of Ota, Hori macules, Naevus spilus, freckles, cafe au lait spots, and other pigmentation-related issues.

What can be treated with the Ruby laser?

The ruby laser emits a wavelength of light that is preferentially drawn to specific skin hues :

- The ruby laser’s 694 nm wavelength is drawn to the skin’s melanin, which causes skin pigmentation. Although it doesn’t attract melanin as much as the Piqo4 laser’s 532nm wavelength does, it penetrates deeper and can reach deeper undesirable pigmentation. To assist break up the pigment, skin pigmentation is typically done in the q-switch (short pulse) mode. For additional details on skin pigmentation, click here. The ruby laser can be used to treat various kinds of skin pigmentation, such as;

- Birthmarks: The Ruby laser can be used to treat a variety of brown birthmarks. However, any elevated lesions cannot be cured. Naevi of Ota, Hori macules, Naevi spilus, Congenital Melanocytic Naevi, and Cafe au Lait Spots are all treatable pigmentation.

sclerotherapy-related pigmentation - Melasma is a hormonally-related pigmentation that can be treated with the ruby laser.

- The ruby laser is quite successful at removing freckles from the body or face.

- Although the Piqo4 laser is typically used for this, the ruby laser is good at removing sun spots and other sun damage.

What will my skin look like after treatment?

The intensity of the treatment will determine this. For 24 to 48 hours, the skin could appear lightly sunburned. The skin may crust and seem darker after pigmentation removal for about a week. The skin may have some minor pinpoint bleeding and turn white after a tattoo removal. Depending on how harsh the treatment is, recovery may take some time. For a few days, dressings and antibiotic ointment may be necessary.

Will it hurt?

Before laser treatments, the region can be numbed using topical anaesthetic. Topical anaesthetic is required, especially when greater energies are employed, as in tattoo removal. Some claim that laser tattoo removal without this anaesthetic is more painful than getting the tattoo in the first place. If necessary, an injection might be administered to make the area more comfortable during treatment.

There may be no need for anaesthesia for lower energy treatments.

Ruby laser case study – freckle removal

This woman came in for a single ruby laser treatment to get rid of the freckles on her face. The freckles have significantly improved after a about 7-day recovery period.

Ruby laser case study – sunspot removal

The patient wished to have a sunspot on her right cheek removed when she first arrived. The after picture was taken two weeks after just one Ruby laser session.

What are the possible adverse outcomes of treatment?

A small number of people who receive laser treatments experience unintended, negative effects. These consist of :

- Post-inflammatory hyperpigmentation is a brown mark that remains on the skin after treatment and normally fades with the help of lightening products over the course of many months.

- Hypopigmentation is the (rare) loss of pigment in the treated area. persistent redness. Sometimes it can take longer than expected for the skin’s redness to go away.

viral or bacterial infection Herpes simplex outbreaks can occasionally be brought on by laser treatments. Any bacterial or viral infection in a laser-induced wound carries the risk of scarring. Scarring is an extremely uncommon potential that is typically linked to darker skin tones, very aggressive energy settings, and bacterial or viral infection.

Permanent hair removal by normal-mode ruby laser

13 volunteers were subjected to normal-mode ruby laser pulses at fluences of 30 to 60 J/cm2 delivered to both shaven and wax-epilated skin in six test regions on their thighs or backs. A control site that had been waxed and shaved was also present. Manual counting of terminal hairs was done both before and after laser treatment. Following laser irradiation, transient alopecia appeared in all 13 subjects, which is compatible with induction of telogen. In comparison to the untreated shaved and waxed control sites, 4 subjects still exhibited apparent, considerable hair loss at all laser-treated locations two years after exposure. Six months, a year, and two years after receiving laser treatment, there was no discernible change in the number of hairs in any of the 4 subjects. Histologically, hair follicles that were tiny and vellus-like were associated with laser-induced alopecia. No scarring and no permanent pigmentary changes were observed.

Ruby (694 nm) Laser Hair removal :

The earliest kind of laser used for hair removal is this one. Light and fine hair types benefit from it the most. People with tanned skin and darker skin cannot use it. Really, individuals with fair or white skin should use it. Ruby Lasers are now widely used for laser hair removal since they are effective and cover a smaller area than other lasers.

Which Fitzpatrick Skin Type is the Ruby laser suitable for?

Skin types I and II can use this laser. For those with fair or light skin, it is great. People with dark skin may not be able to wear it.

What are the advantages of Ruby laser hair removal?

- It is possible to remove hair permanently.

- Compared to other laser hair removal methods, it is rather painless.

- If hair does regrow, it usually does so sparserly and finerly, making it less apparent.

- Because this laser has built-in cooling technology, the risk of burns and any other negative effects from laser hair removal are reduced.

What are the side effects of Ruby laser hair removal?

- White or light hair as well as tanned or dark skin cannot be treated with the ruby laser.

- focuses on a somewhat limited area.

- The modest repetition rate of the laser could make treatment times longer.

- Burns, scars, redness, edoema, and skin discoloration are all possible side effects.

What are the different types of Ruby Laser Devices available?

The following are some popular ruby laser products currently on the market. RubyStar, EpiPulse Ruby, and Palomar E2000.

What are the specifications of the Ruby Laser?

- 694 nm is the wavelength

- Rate of repetition: 0.5 to 1.2 Hz

- 3- to 10-mm spots

- 0.85–3 ms for the pulse width

- Fluency: 5 to 40

RUBY LASER :

When high powered fibre or yag lasers are required, RubyLaser is the machine of choice. It offers exceptional performance in demanding applications with a sturdy casing to assure operator safety, and it shares the same control as the high-end FlexLaser III. Ruby has been able to weld stainless foil 25 microns thick to pressure vessels used in safety backup systems for reactors and refineries thanks to high-quality components. Ruby can also be used to entirely burr-free cut a variety of metals, including industrial diamond with mirror edge quality for drill rigs and high speed machining. Ruby is frequently supplied as a speciality machine with unique tooling and enhanced software.

Ruby Laser Rods

Ruby, which was first shown more than 30 years ago, is still the go-to option for delivering strong, high-power pulses of visible spectrum radiation. In a variety of sizes and with consistent optical quality, Roditi offers Czochralski grown Ruby, enabling predictable system performance. Excellent physical and optical qualities are combined with positive laser performance features in the ruby laser material. The aluminium oxide host has the best heat conductivity of any solid state laser host. It may be manufactured and polished to exacting specifications and is extremely hard and chemically inert.

Ruby’s wide absorption bands are efficiently pumped by commercial lamps to provide a 694.3 nm output with a long luminous lifetime and significant energy storage and gain.

The Ruby Laser Crystal’s optical performance is crucial. Crystals must be created without detectable flaws that might influence their refractive indices.

Large-diameter crystals are developed, producing distinct radial zones with a diameter of over 25.4 mm, sufficient for all rod needs. The crystal structure and distribution of radial chromium are precisely regulated. To confirm chromium levels, optical windows are cut from each crystal and tested for absorption. To consistently deliver laser rods that produce the best beam quality, each rod is interferometrically evaluated for optical quality.

Rod Selection Ruby is available with Cr2O3 substituted for Al2O3 at two distinct levels, 0.03% and 0.05% by weight. The most popular option, though, is 0.05%.

Lasers operating at or close to threshold power can benefit from the 0.03% material’s lower threshold and improved slope efficiency in this constrained region.

situations when it is preferred to pump big diameter amplifiers fully and uniformly in order to prevent the potential degradation of premium beans brought on by the use of higher doping levels.

Applications

- devices with high Q switching power that can produce the energy densities required to produce Thomson scattering in plasma diagnostics.

- Holographic camera systems with high brightness and a long coherent length.

- devices with high output are helpful for frequency doubling into the UV spectrum.

- Systems for working with metal that use lasers may drill holes through tough materials.

- Systems for medical lasers used in cosmetic dermatology and tattoo eradication.

Physical and Optical Properties :

| Density | 3.98 g/cc | Refractive index at 700 nm | 1.7638 Ordinary Ray | ||

| Melting Point | 2040° | 1.7556 Extraordinary Ray | |||

| Young’s Modulus | 345 Gpa | Birefringence | 0.008 | ||

| MOR | 425 MPa | Refractive Index vs. Chromium Concentration | 3 x 10-3 (Δn / % Cr2O3) | ||

| Compressive Strength | 2.0 Gpa | Fluorescent Lifetime at 0.05% Cr2O3 | 3 ms at 300 K | ||

| Hardness | 9 Mhos, 2000 Knoop | Fluorescent Linewidth (R1) | 5.0 Å at 300K | ||

| Thermal Expansion | 20° to 50° C | 5.8 x 10-6 / ° C | Output Wavelength (R1) | 6.94.3 nm | |

| 20°to 200° C | 7.7 x 10-6 / ° C | Major Pump Bands | 404 nm and 554 nm | ||

| Thermal Conductivity | at 0° C | 46.02 W / (m•K) | |||

| at 100° C | 25.10 W / (m•K) | ||||

| at 400° C | 12.55 W / (m•K) | All values are for 60° orientation material | |||

Material and Fabrication Specification :

| Material | |||

| Crystallographic orientation, optical (c – axis) to rod axis | 60° within 5° | ||

| Dopant Concentration: Cr2O3 Weight Per Cent Substitution for Al2O3 | 0.05% ± 0.005% | ||

| 0.03% ± 0.005% | |||

| Optical Quality, Double – Pass Interferometer set for minimum fringes in rod, all diameters to 1.00″ (25.4 mm) | SIQ GRADE | SELECT GRADE | |

| 0.5 fringes / inch of length | 0.25 fringes / inch of length | ||

| Corefree Diameter | 0.756″ and smaller | 0.625″ and smaller | |

| Bubbles, inclusions, scattering sites as viewed in white,focused illuminator light and under crossed polarisers | Free of imperfections visible to the naked eye | ||

| Fabrication | |||

| Diameter Tolerance | ± 0.001″ (0.025 mm) | ||

| Length Tolerance | (Plano / Plano) | ± 0.030″ (0.75 mm) | |

| Barrel Finish – Standard | 30 microinch CLA | ||

| Polished Barrel Finish – Special Order | 80 – 50 | ||

| End Face Bevel | 0.005″ / 0.010″ (0.1 / 0.25 mm) non – focusing radius type;bevel to 0.013″ allowed to remove chips on large rods | ||

| Chips | None on polished and faces. Up to 0.012″ (0.3 mm) allowed to lie in area of bevel and extend into barrel surface | ||

| Flatness | Rod Diameters 0.590″ (15 mm) and smaller | 1 / 10th wave over 90% of diameter | |

| Rod Diameter 0.625″ (16 mm) and larger | <1 / 5th wave over 90% of diameter | ||

| Parallelism of ends faces (measured geometrically with autocollimator and precision rotary table; 2 readings 90° rotation) | |||

| Plano / Plano | 10 seconds of arc or less | ||

| Wedge / Wedge | 20 seconds of arc or less | ||

| Brewster / Brewster | 30 seconds of arc or less | ||

| Perpendicularity of end faces to rod axis | Standard | 5 minutes of arc or less | |

| Special Order | 2 minutes of arc or less | ||

| Surface Finish (viewed in low – angle, reflected light from high – intensity | Standard | 20 – 10 | |

| microscope illuminator with condenser, by naked eye and 5X loupe) | Special Order | 10 – 5 | |

| Brewster Angle | 20° 34′ | ||

| Brewster Angle Tolerance | ± 30 minutes | ||

| Wedge Angle | 15′ to 8° | ||

| Wedge Angle Tolerance | ± 10 minutes | ||

| Anti – Reflection Coating | Single layer magnesium fluoride, suitable for high power laser operation. Reflectivity at 694 nm is less than 0.25% per end face. | ||

| Meets adherence and abrasion resistance of MIL – C – 48497 | |||

Continuos wave diode pumped ruby laser :

Although most ruby lasers are pulsed, continuous wave (cw) ruby lasers are also a possibility. I demonstrate in this post how I was able to create such a system without the need of arc lamps, using only a laser diode as the pump source.

Although most ruby lasers are pulsed, continuous wave (cw) ruby lasers are also a possibility. I demonstrate in this post how I was able to create such a system without the need of arc lamps, using only a laser diode as the pump source.

Motivation and Background

I’ve always wanted to build a ruby laser, but I’ve never fully thought through a concept. This changed after I saw a study by Dr. Walter Luhs and Prof. Dr. B. Wellegehausen that showed a cw diode-pumped ruby laser—the first one, in fact—along with detailed instructions on how it operates. So, after some investigation and speaking with Dr. Luhs, I was able to obtain the laser’s optical components (mirrors and ruby crystal). I’m extremely grateful for Dr. Luhs’ tremendous assistance!

Ruby laser theory

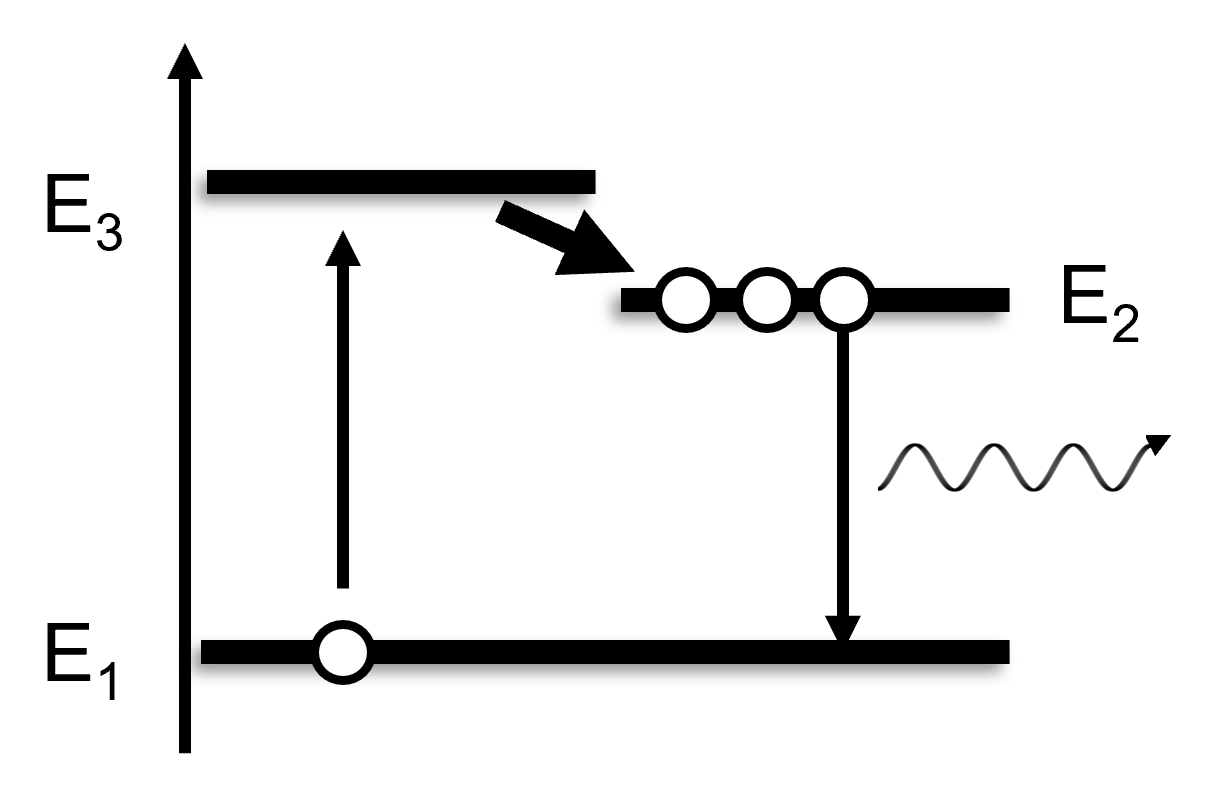

A large amount of pump energy is needed to operate a ruby laser. This is due to the three-level system used by the Cr3+ Ions in the ruby crystal, which technically is an aluminium oxide crystal with Cr dotations.

When an electron in this system is excited, it is transported to E3, where it stays for a short while before falling back to E2. This prevents it from returning to E1, which would obstruct laser action. After that, it can revert to E1, releasing a photon (694 nm) in the process. After about 3.2 ms, either through spontaneous emission or if it is struck by another photon of this wavelength, this occurs. The latter is the essential component of light amplification and is known as stimulated emission (Laser = Light amplified by stimulated emission of radiation).

A population inversion between E1 and E2 is required for light amplification and, consequently, laser action, meaning that there must be more electrons in the excited state (E2) than in the ground state (E1). This implies that for any form of laser output, more than 50% of all the atoms in the ruby must be excited, disregarding E3 due to its extremely short lifetime. Therefore, the crystal needs to be intensely pumped, which is typically accomplished by powerful flashlamps. High power argon lasers and mercury vapour lamps, both complex systems, have been employed to continuously deliver these kinds of optical intensities. However, until 2019 diode lasers were never used to continuously pump ruby lasers.

When examining the ruby’s absorption spectra, it appears that 405nm and 540nm are absorbed the greatest. Fortunately, 405nm Laser diodes are available and reasonably priced on ebay (as part of fluorescent display modules). Their output powers range up to 1W.

Experimental setup

The configuration of the laser system is shown above: We must narrow the beam of laser light in order to produce high intensity laser light. This requires collimating the beam first because it is challenging to achieve from a highly divergent beam (typical of laser diodes). The ruby crystal is intended to be the focal point. This crystal is 5mm long, 3mm in diameter, and coated on both sides with an AR coating for 694 nm. The pumpdiode and mirrors must be appropriately positioned to provide laser activity. The hemispheric resonator, however, makes the planar mirror much less important:

No matter how S1 rotates, a resonant path is still conceivable as long as the distance between the two mirrors is less than the radius of S2 (within certain bounds, of course). Only S2 and the pumpfocus need to be aligned as a result. There are four requirements that must be fulfilled:

- The crystal’s pumpfocus must be there, ideally in the centre: high level of pumping

- The radius of S2 should be equal to or less than the resonator length: Stability of the hemispheric resonator’s optics

- The pumpvolume and modal volume’s axes of symmetry must match: enough laser beam gain and optical stability

- The modal volume must be less than or equal to the pumpvolume. Gain of the laser beam is sufficient.

The volume that the source pumps into the laser crystal is known as the pumpvolume (light blue). The lasermode’s volume is represented by the modal volume (dark blue), which is determined by the location and radius of S2. The modal volume must completely match the pumpvolume since only the atoms within this volume may provide gain. Outside of the pumpvolume, any portions of the modal volume do not undergo gain and cannot thus be included in the laserbeam. Making the modal volume completely correspond with the pump volume is also crucial (criteria 3). Only if the pumpvolume is physically greater than the modal volume can this be the case.

Advantages of Ruby Laser | disadvantages of Ruby Laser :

Benefits or advantages of Ruby Laser

Following are the benefits or advantages of Ruby Laser :

- They are affordable.

- Ruby lasers have a smaller beam diameter than CO2 lasers.

- The output power of a ruby laser is comparable to that of a He-Ne laser.

- Ruby is a solid, thus there is no danger of wasting any of the active medium’s substance.

- They are referred classified as class-I lasers because of their modest output power. They are therefore utilised as toys for kids. They can also be utilised as artistic displays and pieces of décor.

Drawbacks or disadvantages of Ruby Laser :

Following are the drawbacks or disadvantages of Ruby Laser :

- Only after at least half of the ground state electrons have been excited to the meta stable state does a considerable amount of stimulated emission occur in a ruby laser.

- This type of laser has a relatively lower efficiency.

- Compared to other laser kinds, this one’s optical cavity is small.

Ruby Laser – History, Properties and Applications :

A solid-state laser known as a “ruby-laser” uses a man-made ruby crystal as its gain medium. Theodore H. “Ted” Maiman created the first ruby laser at Hughes Research Laboratories in 1960. It emits red visible light pulses with a wavelength of 694.3 nm. Synthetic ruby, which serves as the active laser medium, is energised by optical pumping through a xenon flashtube.

Laser Properties :

| Laser Properties | |

|---|---|

| Laser type | Solid |

| Pump source | Electrical discharge |

| Operating wavelength | 694.3 nm |

Physical and Chemical Properties

| Laser Properties | |

|---|---|

| Chemical formula | Al2O3:Cr |

| Crystal structure | Cylindrical |

| Melting point | 2040°C |

| Hardness | 9 |

| Thermal conductivity | 46.02 W/mK |

| Young’s modulus | 345 GPa |

Applications :

One of the initial uses for the ruby laser was rangefinding. Initially, tunable dye lasers were optically pumped using it. Due to its low efficiency and repetition rates, it is rarely employed in industry.

Some typical applications of ruby laser include the following:

- Systems for laser metalworking that can drill holes through tough materials

- devices with high power for frequency doubling in the UV spectrum

- Medical laser systems for aesthetic dermatology and high-brightness holographic cameras with long coherent length

- Q-switched system with high power.

Conclusion

The Ruby laser is a type of solid-state laser that operates in the red part of the electromagnetic spectrum. It was one of the first lasers ever developed and played a significant role in the advancement of laser technology.

The Ruby laser gets its name from the ruby crystal used as the gain medium. The crystal is typically made of synthetic ruby, which is a form of aluminum oxide (Al₂O₃) doped with small amounts of chromium (Cr) ions. These chromium ions act as impurities within the crystal structure and are responsible for the laser’s ability to emit light.